Articles & Videos

The Up and Up of North American Smart Manufacturing

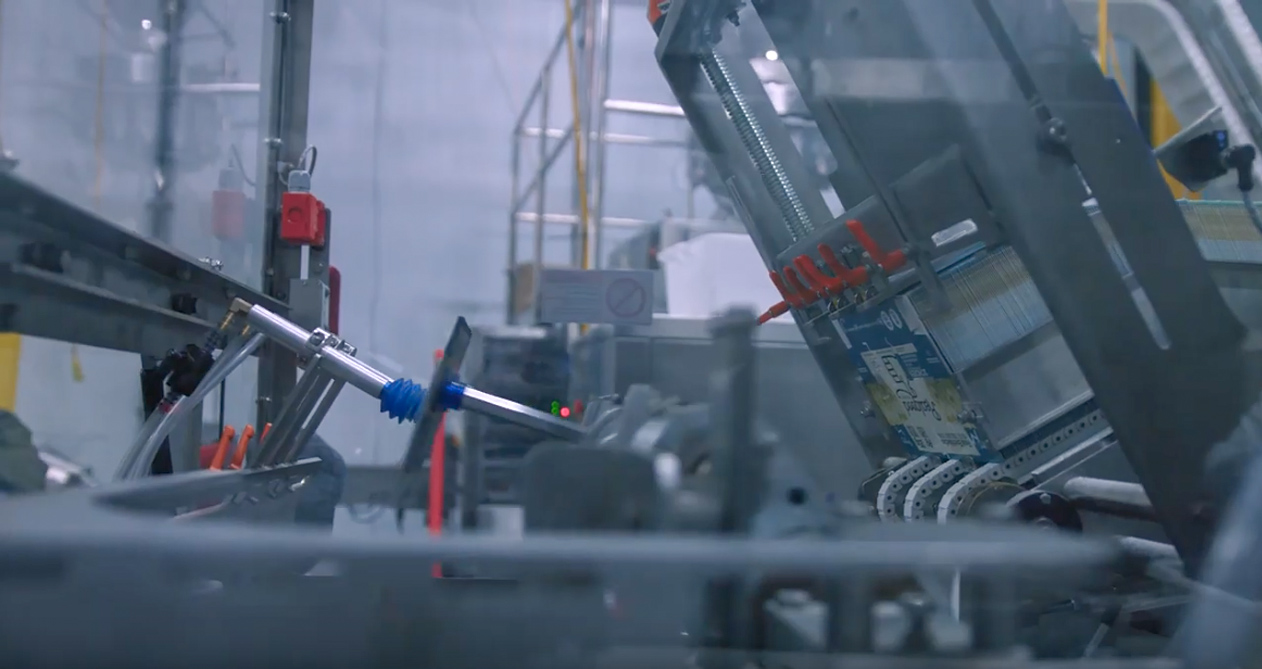

Since the turn of the century, manufacturing has evolved greatly. As new, advanced technologies drive the industry forward, manufacturing is clearly heading for a more automated, information-driven future and it’s known as Smart Manufacturing.

According to The North America Smart Manufacturing Market report, the North American smart manufacturing market is expected to reach a CAGR of 22.3% from 2019 to 2026. Manufacturers across all industries in North America are laying the foundation for future advancement by increasing their level of automation.

Besides this, North America has been developing and adopting robotic and automation technologies to compete with global manufacturing hubs like China and Japan. Consequently, smart manufacturing and industrial control systems have gained traction in the region as a way to cut energy costs and gain cost benefits.

What is Smart Manufacturing?

A smart manufacturing (SM) process involves digitizing all aspects of manufacturing, including product design, supply chain, production, distribution, and sales. Manufacturing companies can stay agile and make quick adjustments to their business models by analyzing data from all phases in the manufacturing process through machine learning, artificial intelligence and connected robotics.

The North American smart manufacturing market has a moderate level of competition and is dominated by several major players. Major companies are expanding their customer bases internationally to expand their market share. Recently, there have been the following developments…

As part of their Advanced Redundant Control System (ARCS), Emerson has announced a solution for various emergency shutdown valve applications in the chemical, power and oil and gas industries.

A partnership between Rockwell Automation and Microsoft has resulted in integrated, market-ready solutions that allow manufacturers to scale digital agility.

Technologies that Drive Smart Manufacturing in 2022

A wide range of technologies are involved in smart manufacturing. There are three main categories of these technologies: robotics, artificial intelligence, and the Internet of Things. Each of these categories contains various technologies, which often overlap. As an example, IoT sensors provide data that AI technologies for manufacturing can use.

Robotic Process Automation

The robotic process automation process automates software tasks to simplify employee manual labor. It is not to be confused with physical hardware robotics. Several tasks can be automated, including:

- Tasks related to back-office operations

- Keeping track of AR/AP

- The management of vendors

- Management of inventories

Robotic process automation can be used for many other purposes, but automating tasks like these are necessary for smart manufacturing in 2022. Over 180,000 robots have been dispatched to various American companies in the last five years, creating more than 1.2 million new jobs in manufacturing. U.S. industrial robot demand is heavily influenced by automotive manufacturing, followed by electronics, plastics, and chemicals, says MIT; as a result, robotic process automation (RPA) is expected to grow in North America.

Machine Learning and Artificial Intelligence

AI plays a crucial role in smart manufacturing. The aim of complex AI and machine learning algorithms is to maximize the efficiency of existing technologies, maintain machinery, and maximize factory productivity while generating the least amount of waste.

Predictive maintenance is one of the most popular applications of machine learning in smart manufacturing. It is costly for businesses to wait until machinery breaks down before performing maintenance. In combination with IoT sensors, ML algorithms can predict when machines need to be serviced ahead of time, preventing breakdowns. Other applications of machine learning in manufacturing include visual inspection using machine vision.

Digital Twins

It is a concept that is born from the idealistic nature of how artificial intelligence is used. When it comes to testing the efficiency of our production line layout, it’s not always easy to find the most efficient way. Digital twins solve this problem by digitizing the testing process. It is possible to reorder and modify the production line pieces by digitizing the factory floor into a simulation based on reality.

A digital twin, however, is not the same as a simulation. In contrast to static simulations, engineers can view data based on actual conditions. A real-world sensor collects this data.

Cloud Technologies

There are several reasons why manufacturers are shifting to cloud storage networks to store data securely. For instance, manufacturers can access data securely from anywhere in the world on demand. In addition, cloud storage is cheaper than on-premises storage. Companies can reduce IT support and hardware costs by storing their data in the cloud.

Internet of Things (IoT)

Artificial intelligence is often perceived as a game changing technology on its own. However, the use of machine learning and artificial intelligence is heavily dependent on data. The Internet of Things has made artificial intelligence an increasingly useful tool in manufacturing environments in recent years. Industrial sensors have enabled AI applications like predictive maintenance, digital twins, automatic power management, and quality assurance powered by computer vision.

Opportunities for Manufacturers Interested in Embracing Smart Manufacturing

Smart manufacturing is envisioned as a way to drive even greater profitability for organizations, as it can extract more output from the same resources. By using smart technology, manufacturers can predict potential issues in advance. When IoT is in place, systems can identify when problems may arise and what machinery needs to be repaired. Aside from that, augmented reality (AR) provides real-time guidance to employees to prevent mishaps. Using Industrial IoT sensors, manufacturers can improve performance and achieve tangible results.

Using industry 4.0 solutions at a smart factory, manufacturers can keep an eye on inventory and quality more effectively. They can increase efficiency by automating asset management and optimization tasks, including reclassifications and transfers.

Challenges For Manufacturers Implementing Smart Manufacturing

Costs associated with smart manufacturing implementation are one of its biggest challenges. Besides technology being expensive initially, expertise in implementing the technology is also a major factor to consider. Knowledge of newer fields such as IoT, augmented reality, and artificial intelligence can lead to budget constraints.

Often, there is a lack of direction when establishing objectives when launching Industry 4.0 initiatives. Frequently, too many stakeholders are involved in these cross-functional projects which can lead to conflicting goals and result in projects being stalled before they come to fruition.

Cyber security is another key challenge associated with smart manufacturing. 58% of manufacturers participating in the “Accelerating Smart Manufacturing” report were concerned about privacy and intellectual property protection. The “Accelerating Smart Manufacturing” survey found that 62% of companies are continuing or ramping up their technological initiatives despite these challenges — which they expect will be resolved as smart manufacturing becomes more widespread.

Smart Manufacturing is a Global Movement

Smart manufacturing has become one of the focuses of governments around the world; partly because of the vulnerabilities that were exposed during the pandemic and somewhat due to the movement to net-zero and a desire to reduce the need for air travel in the movement of goods. Many governments are placing a high priority on domestic manufacturing since it generates high-paying jobs, drives technological innovation and contributes to economic growth in multiples. A large number of benefits and opportunities await manufacturers and governments will no doubt continue to increase their investments in domestic manufacturing. Implementation costs may be a barrier for some SMEs currently as they contend with rising costs and interest rates and investment into the company takes a back seat.

Sallyport Commercial Finance assists many clients in the manufacturing industry in achieving their growth ambitions. If you have plans for growing your manufacturing business and need the working capital to make them happen, reach out to our team today.

Search

News

$1M Funding Fuels Agri-Business Growth Across Borders

Sallyport is pleased to announce a new partnership with a Canadian agriculture business, providing a $1,000,000 Accounts Receivable facility to…

Read MoreFueling EdTech Growth with $5.5M in Tailored Financing

Sallyport is excited to support a forward-thinking education technology company with a $5.5M combined Asset-Based Lending facility, including Accounts Receivable…

Read MoreArticles

Harnessing Growth Opportunities in the Beauty Industry

The beauty industry is big business and it’s getting even bigger. Globally, sales reached $511B in 2021 and are estimated…

Read MoreA Guide to Accounting for Factored Receivables (inc Example)

When you begin invoice factoring, your invoices are transferred to the factoring company for collection and they cease to be…

Read MoreVideos

Popkoffs Client Testimonial

Popkoffs Client Testimonial

View NowAG Machining Client Testimonial

AG Machining Client Testimonial

View Now